|

|

特点

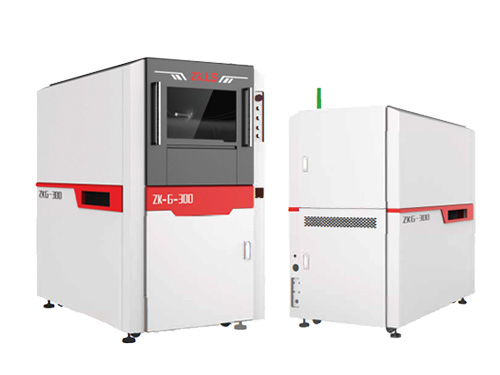

全自动PCB激光打标机是一款专门用千在印刷电路板上标刻条码、二维码和字符、图形等信息的专用机型。本设备可直接对接SMT流水线,

全自动化生产,生产过程中无需人工操作,也可配合自动上下板机组成离线式工作站,一台设备可对应多条流水线。

1. 伺服XY运动平台,工业PC控制、模块化柔性化编程设计。

2标配绿光激光(也可选其他激光),最小可雕刻出1.6mmx1.6mm多达1创立字符的二维码。同

轴CCD技术,精密定位,并且读取、识别二维码等级(适应AMI DPM A, S9132等标准)。

3. 三色光源照明:颜色可三色切换,方便读取不同颜色板的雕刻标志。

4传送皮带距地面900士30mm, 可以直接对接SMT。可以自选进出料运动方向。

5. 标准SMEMA接口及网络通信功能,可与上、下游设备及服务器进行通讯;

6. 烟尘过滤装置,有效去除标记时产生的粉尘保证干净及健康。

7. 主动防呆,软件自动检测并防止错打,漏打;主门配有安全开关锁,由软件控制,

8. 在雕刻过程中各门都无法人为开启,防止产品不良;

9. 进出料口配有自动遮挡门防止激光雕刻时强光损害人眼

Characteristics

1.XY Servo Operation Platform,lndustrial PC Controlled、M odular and flexible programming design.

2.Standard Configured Green Laser (Option Of Other Laser) ,

minimum carving of 1.6mm x 1.6mm up to 16 characters two-dimensional code

3.Coaxial CCD technology, precise positioning, read and identify two-dimensional code level

(adapt to AIM, DPM, AS9132 and other standards).

4.Three Color Light Source, Capable to swap between 3 color ,It is easy to read the engraving mark of different color boards。

5.Process Height 900这0mm, capable to In Line with SMT. Programmable Board Flow Direction。

6.Standard SMEMA Interface & Lan Communication ,capable to communicate with Upstream & Downstream machines;

7.Dust filter can effectively remove the dust throughout the process to ensure cleanliness and health

a.Active stop, software automatically detects and prevents any wrong hit or miss;

the main door is equipped with safety interlock, controlled by software

9.AII covers cannot manually open throughout the process

1 O.The inlet and outlet are equipped with automatic barrier to prevent laser from damaging human eyes during laser engraving

Automatic PCB laser marking machine is designed for ma卤ng bar code, 2 dimensional code, characters and graphics on PCB

surfaceT. his machine is capable to in-line ope「ation with SMT lines, fully automatic operation with human power not required.

Besides, it is also available to work together with loade「/unloader and operate in off一line mode. One laser marking machine can

fulfil the capacity of several p「oduction lines.

加工性Process

Parameters

主要配置

Configuration

使用环境条件

Env1ronmenal

Requirement

I 激光光源Laser Source I

激光波长Wave Length

电路板尺寸Board Size

电路板后度Board Thi ckness

重复定位精度Repeatability

最小线宽Min Lase「Width

支持条码类型Code Compatible

进板方式Board Flow

电动工作平台Electrical Worktable

定位系统Positioning

外部辅助装冒External Hardware

(选配)电源保护Power Protaction

供电规格PowerSuppl y

供气规格Air P「essu「e

环境要求Tempe「ature

整机尺寸Dimensions

I 紫外Untraviolet/绿光Green Light I

355nm/532nm

最小Min 50mm x 50mm、最大300mmx300mm

(特殊可定制Custom Made available )

0.6-4mm (特殊可定制Custom Made Available)

士0.02mm

<0.005mm

Code128、Code39、EAN-8、UPC-A等条码Bar Code, DataMatrix、QR等

二维码2D Code

左进右出/右进左出(可选) L-+ R/R-+ L (Selectable)

X-Y线性模组Linear Modules

旁轴CCD相机CCD Side Mounted Camera

负压吸附抽尘系统Vacuum Dirt & Dust Removal Unit

UPS, 断电可持续运行10分钟Standby Power Supply, 10 min operation if power

failure

220V /50 Hz/2KW

0.6Mpa

温度Temp 5-25"C, 湿度Hum昢ty < 50%

930mmx1600mmx1650mm

上一篇:没有了

下一篇:全自动PCB绿光激光打标机